Forecasting warehouse staffing needs with Long short-term memory (LSTM) recurrent neural networks (RNN)

Advanced Analytics Center of Excellence (AACoE) was invited to speak about an exciting AI-powered tool we built on Deep Learning that improves warehouse staffing and planning.

If you haven’t heard, Deep Learning is the next big thing in the field of Artificial Intelligence (AI). Originally conceived in the early 50’s, Deep Learning is a collection of learning algorithms that imitate human neural networks’ learning mechanism, which allows systems to learn specific tasks extremely well. When given enough training time and data, this powerful capability can perform these tasks better than humans. For example: notice how your Apple photo album (or Android google photos) automatically tags you, your family, your pets and even places you’ve been to in your photos. The underlying AI is running a sequence of what’s called convolutional neural networks (that combines simulated pattern-finding filters and neural networks) to identify consistently occurring objects/animals/humans from your pictures.

Here’s a previous blog where we painted the ATD Logo, Picasso Style by using convolutional neural networks to Transfer Painting Styles (PyTorch).

These convolutional neural networks see images so well that it’s beating professional doctors in accurately identifying lung cancer from CT scans. In similar ways, deep reinforcement learning helps Tesla cars drive themselves. It also guides SpaceX rockets by enabling them to land themselves. Recurrent neural networks also make translating different languages easy and convenient through simple Google translate. In many ways, Deep Learning is supercharging the tech industry to accomplish many previously thought impossible AI tasks.

And now Deep Learning is right here at ATD.

As the largest tech-enabled tire distributor in North America, ATD has more than 140 distribution centers in the U.S. and Canada, employing thousands of warehouse associates. With each distribution center located in different geographic locations and servicing a variety of customers, these DC’s require different staffing levels in order to operate efficiently. Each Distribution Excellence Manager (DEM) is responsible to ensure their DC is staffed with the appropriate number of associates in order to get product to our customers.

When looking at how to staff each DC, we asked:

· What are the variables of the staffing levels?

· Are they constant throughout the week?

· Are there different warehouse activities that happen at different times of the day?

· Is there room for efficiency improvement?

Our DEM’s are tasked with managing facility operations, including seeing our deliveries to our customers. For our DC’s to be efficient and safe, they need to be staffed with the right amount of associates. If we’re short staffed, we’re not able to get the product to the customer. But if we’re over staffed, there may be safety issues and increased operational costs. To help resolve this problem and enable our DEM’s with a more efficient way to staff their DC’s, we started to develop a DC staffing tool.

The main purpose of this tool would be:

1. To provide visibility of warehouse activity levels ahead of time so each DEM is able to staff and plan early and scientifically.

2. To recommend detailed resources (hours and headcount) required by time of day, day of the week and day-by-day into the future.

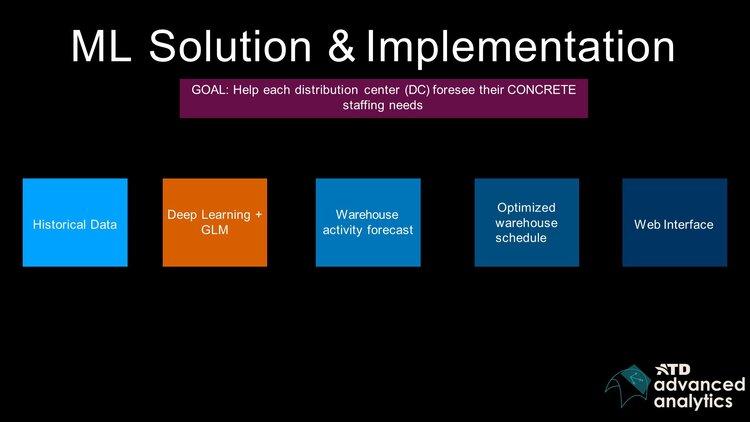

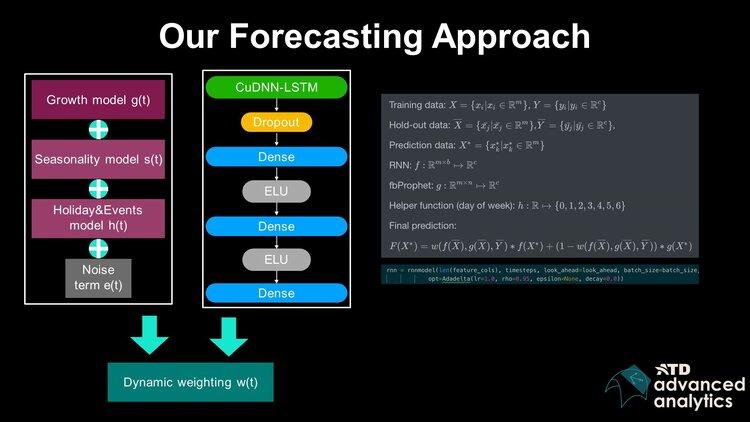

To do this, we developed the tool with five main components (shown above). We started analyzing data, mainly historical warehouse activity data, that we gathered from our handheld scanners. We also layered in sales data, vendor delivery data, outbound delivery data and product data. This gave us the core dataset needed for us to see how busy any given DC has been, what tasks occurred and how these tasks were being fulfilled for the past few years, down to the minute.

With this rich dataset, we were then able to run forecasting algorithms that could forecast daily activities by task type for each DC. This provided visibility for the DEM’s to see what their DC activity level would be for the next two weeks, day by day. BY having this forecast (accuracy ~85%-94%), a DEM can react to business needs and optimize their staffing needs ahead of time.

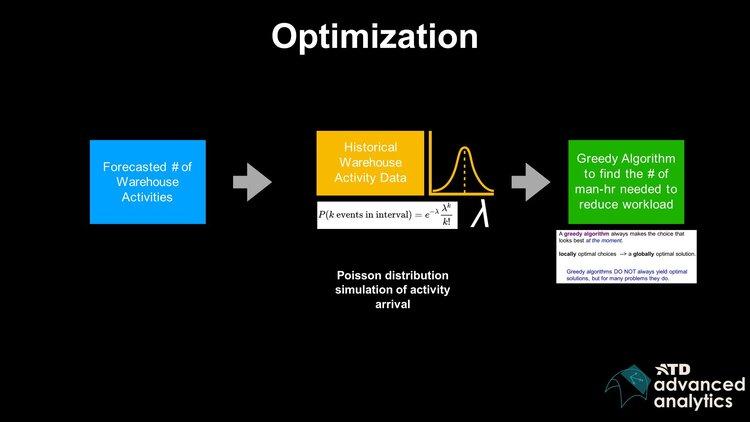

Now that we had a good forecast of warehouse activity levels, we needed to think about how this forecast influences the resources needed in the future. We achieved this goal by running an optimization algorithm on top of our daily warehouse activity forecast. The main idea was to study how activities arrived and occurred at each of the DC’s, minute by minute, by constructing a Poisson distribution using historical handheld data. We then used the Poisson distribution to simulate how those forecasted activities happen in the future and calculated what the required resources were to fulfill those tasks and activities.

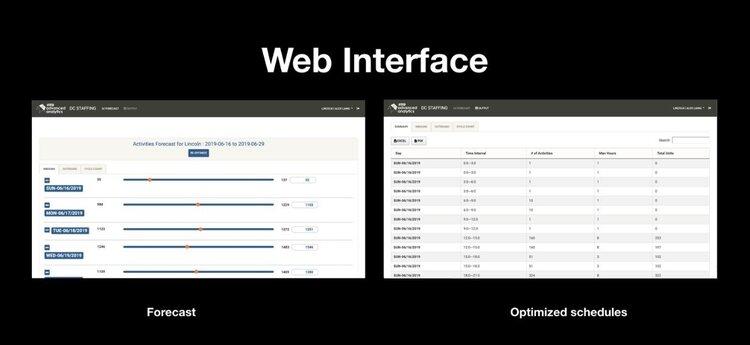

On the front end, we displayed these two results in a web portal, which is a simple way for the DEM’s to quickly see their DC activities.

We’ve now launched this tool to over 120 DC’s across North America, enabling our DEM’s to staff and plan efficiently for their warehouse operations. We’ve built thousands of Deep Learning models that can generate forecasts and many simulations have been run to generate resource recommendations.

Being able to present this work at the Applied AI Summit has been a rewarding and inspiring experience. ATD is pushing the AI revolution by applying state-of-the-art approaches into real world applications and solving concrete business problems in a traditional industry (that isn’t tech or robotics). This is another step in ATD’s digital transformation and we look forward to sharing more exciting projects and tools with you in the future!